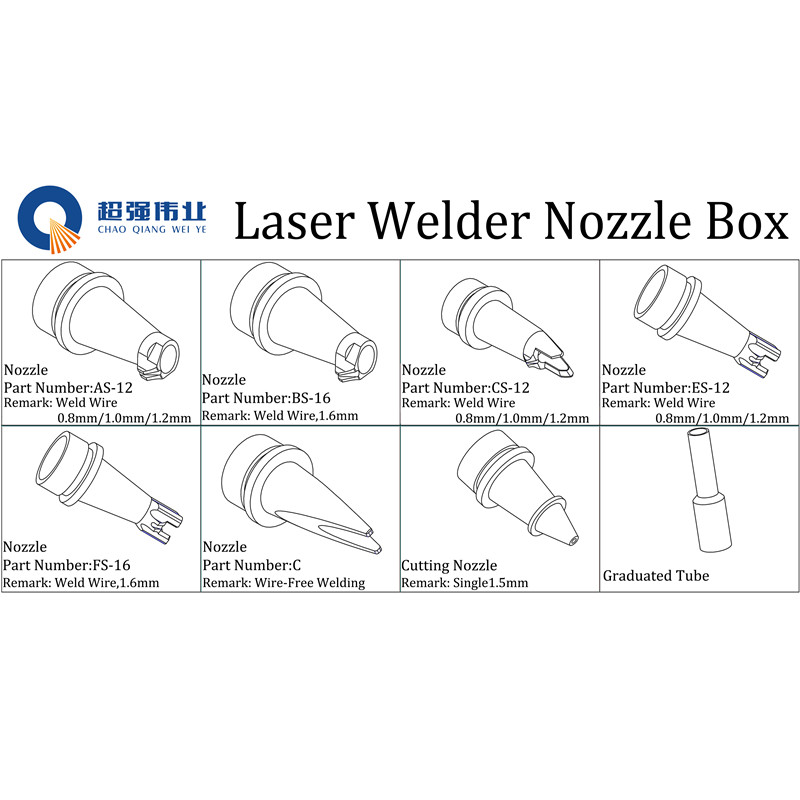

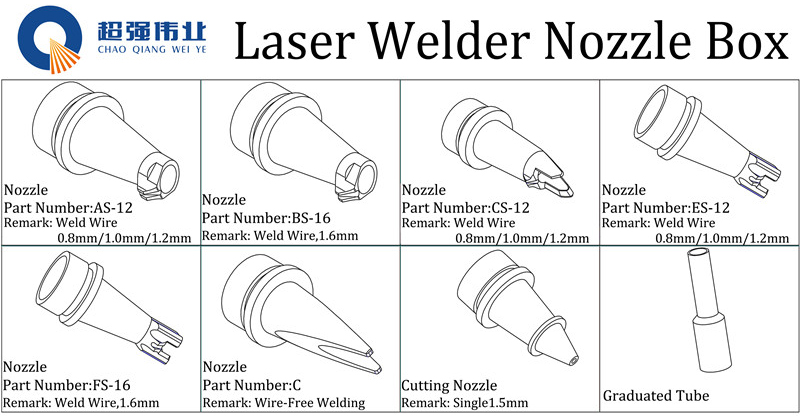

Copper Nozzle for Welding Head

Part Number:AS-12

Remark: Weld Wire 0.8mm/ 1.0mm/1.2mm

Part Number:BS-16

Remark: Weld Wire,1.6mm

Part Number:BS-16

Remark: Weld Wire,1.6mm

Part Number:ES- 12

Remark Weld Wire 0.8mm/1.0mm/1.2 nm

Part Number:FS- 16

Remark: Weld Wire,1 6mm

Part Number:C

Remark: Wire -Free Welding

Part Number:C

Remark: Wire -Free Welding

Part Number:C

Remark: Wire -Free Welding

Graduated Tube

The impact of the nozzle of the laser cutting machine in laser cutting?

Laser cutting machine in use will certainly use the nozzle, the market is mainly divided into supersonic nozzle and subsonic nozzle, supersonic as the name implies that the gas flow rate is greater than the speed of sound, subsonic nozzle is the gas flow rate is less than the speed of sound. The two nozzles are divided into odd and even two kinds. Let's take a look at the impact of the nozzle of the laser cutting machine when laser cutting.

Dual laser laser cutting machine

Before saying that the nozzle of the laser cutting machine has an impact on laser cutting, first say that the auxiliary gas plays a role in cutting. First, speed up the cooling rate of the cutting surface, reduce the heat affected zone, and help form a smooth cutting surface. Second, oxygen as an auxiliary gas can increase the reaction heat, more conducive to thick plate cutting. Third, inert gas as an auxiliary gas can prevent the workpiece oxidation, maintain the characteristics of the material itself.

1. Influence of oxide viscosity

Among all the technological parameters of laser cutting, the auxiliary gas pressure and gas flow characteristics are the important factors affecting the cutting quality. When cutting thick steel plates, such as carbon steel, oxygen is used as an auxiliary gas because iron oxides have a lower viscosity and are easier to remove from the cut.

Under normal circumstances, although the side of the carbon steel laser cutting incision contains a thin layer of iron oxide, in most cases, the quality of the laser cutting carbon steel cutting surface is acceptable. But because stainless steel contains chromium, and molten chromium oxide has a high viscosity, easy to bond in the incision side wall, so the same use of oxygen as an auxiliary gas, stainless steel processing quality is worse than carbon steel. If the gas pressure is not high, it is difficult to remove these oxides.

The same problem will occur when cutting aluminum and titanium alloy, because molten aluminum and titanium oxide also have higher viscosity, in order to obtain good cutting quality must require higher pressure of auxiliary gas. In fact, Cr, Al, Ti alloys are difficult to cut materials.

Laser cutting machine cutting technology display

2. Influence of slag viscosity in melting state

Laser cutting with inert gas as auxiliary gas can alleviate the impact of the above problems to some extent, but the inert gas usually needs to work in a very high pressure range of 8 to 25Bar, and the molten metal in the incision can be taken away under the action of airflow shear force. Because there is no oxygen in the flow, metal oxides will not form in the cut. In general, the pure metal in the molten state has a much lower viscosity than its oxide and can be blown away more easily, so it is easy to form a smaller heat affected zone and a smoother cut surface without oxide impurities.

The special structure of supersonic nozzle can almost convert the pressure of auxiliary gas into dynamic energy, blow away the slag, and achieve a more perfect laser cutting surface.